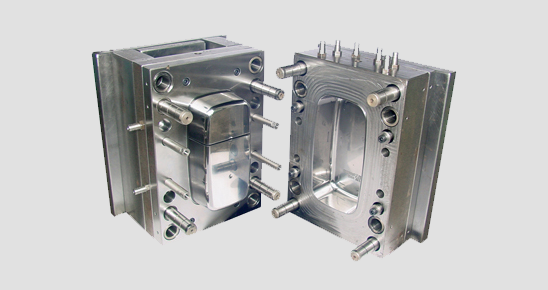

Tooling

IP Injection Molding prides itself in working closely with our customers as part of our up front quality planning to insure that products and tools are designed and developed to be cost effective and manufacturable. Our experienced engineering staff is here to assist in product design, tool fabrication, decorating, assembly and packaging.

Our experience in keeping our customers on budget and on time is

unparalleled in the industry. This could be any type of tool from a short lead-time prototype mold to a multi-cavity high production mold. We

currently run molds from 1 cavity to as high as 120 cavities. Our strength

in providing part design assistance and creative solutions to tooling

challenges assures that your project will be completed on time and will

be to your total satisfaction.

We are able to provide a variety of finishing & decorating options to meet your product requirements. Examples of decoration and part finishing include:

We provide our customers with…

- A resource to improve and refine their design

- Prototypes

- Immediate quotes insuring a more rapid product launch

- Aggressive lead time, with on time tool delivery

- Total satisfaction

We have the ability to provide our customers with tooling that is tailored to their unique needs. Let us know how we can help you. Click here.